| Parameter | Specification |

|---|---|

| Airflow Capacity | Up to [X] CFM |

| Pressure Range | Up to [X] Pa |

| Inlet Configuration | Double Inlet |

| Motor Type | External Rotor / Standard AC Motor |

| Voltage Options | 230V / 415V (Single & Three Phase) |

| Blade Type | Forward / Backward Curved |

| Mounting Style | Base / Flange / Custom Mount Available |

Centrifugal Blowers – Double Inlet

At VBM Enterprises, our Double Inlet Centrifugal Blowers are designed for applications that require maximum airflow output with high operational efficiency. By drawing air symmetrically from both sides of the blower, these units provide a balanced and stable airflow, making them ideal for large-scale HVAC systems, air handling units, and ventilation setups.

Engineered with precision-balanced impellers, robust casings, and CE-certified motors, our double inlet blowers are built for continuous duty, low vibration, and long service life.

High Efficiency | Balanced Air Intake | Industrial-Grade Design

Specifications:

Single Inlet signifies that the air is drawn from two side of the blower and exited from one outlet.

Key Feature

- Double-Sided Air Inlet for high airflow volume

- Efficient Pressure Distribution

- Stable and Low-Vibration Operation

- Backward or Forward Curved Impeller Options

- CE Certified Motors with Variable Speed Options

- Durable Construction in MS, GI, or Aluminum

- Ideal for Large Air Handling Requirements

Applications

- Central HVAC and AHU Systems

- Industrial Ventilation Systems

- Clean Room Air Circulation

- Textile Drying & Processing Units

- Pharmaceutical and Food Manufacturing Facilities

- Paint Booths and Spray Dryers

- Large-Scale Cooling and Exhaust Systems

Why Choose Double Inlet Blowers?

Double Inlet Centrifugal Blowers are specifically designed for applications requiring uniform, high-volume airflow. By drawing air from both sides of the impeller, they deliver enhanced performance with improved pressure stability, making them highly effective in larger systems where consistent air movement is critical.

Customization & Engineering Support

Need specific sizing, pressure requirements, or voltage compatibility? VBM offers full customization, including:

Impeller material and diameter

Motor speed and insulation class

Casing design and mounting options

Coatings for corrosion resistance

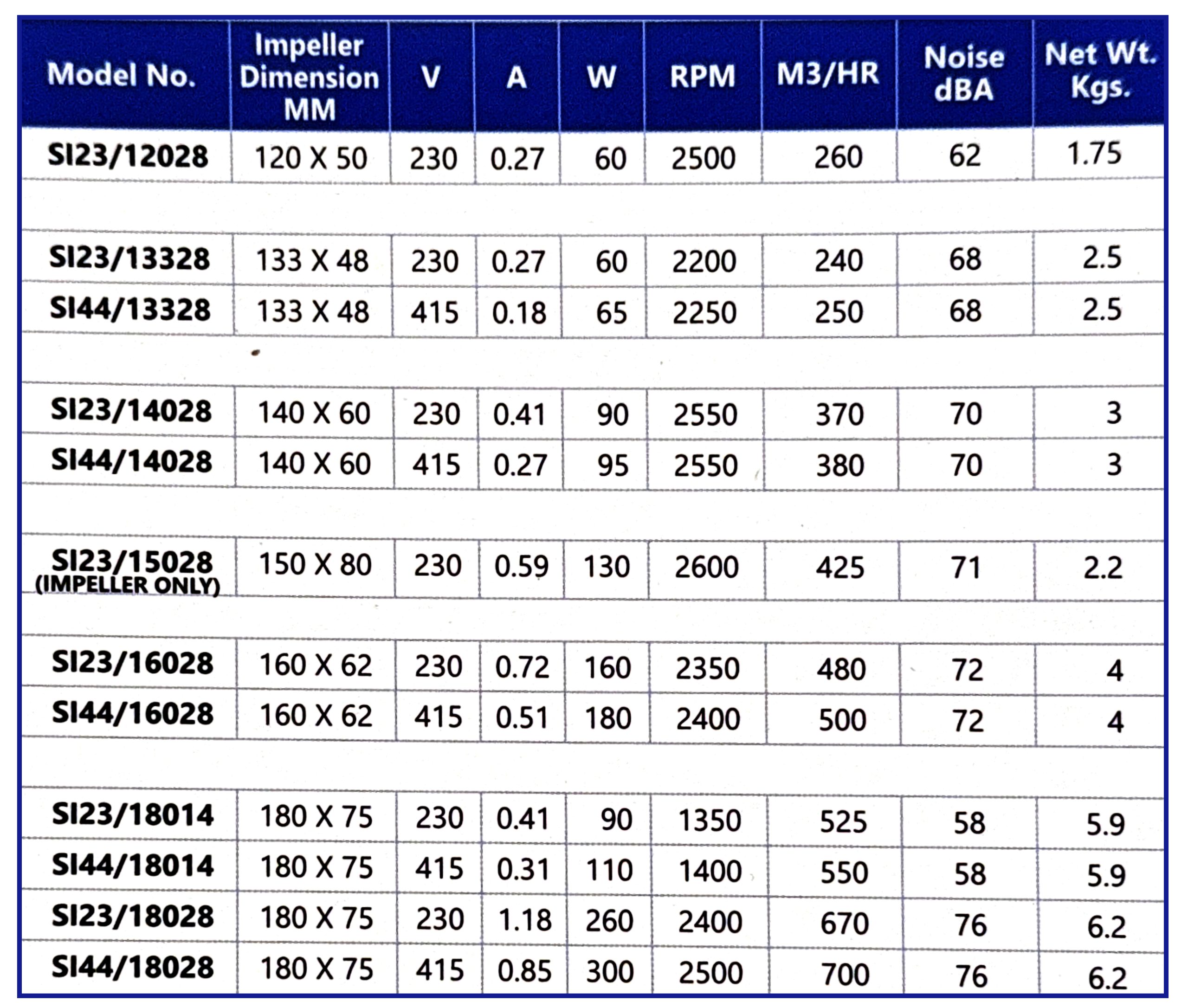

Model Description

| Model No. | Impeller Dimension (MM) | V | A | W | RPM | M³/HR | Noise (dBA) | Net Wt. (Kgs) |

|---|---|---|---|---|---|---|---|---|

| DI23/133×120/28 | 133 × 120 | 230 | 0.54 | 120 | 1800 | 600 | 70 | 3.5 |

| DI44/133×120/28 | 133 × 120 | 415 | 0.38 | 135 | 1800 | 620 | 70 | 3.5 |

| DI23/133×180/28 | 133 × 180 | 230 | 0.86 | 190 | 1850 | 685 | 72 | 4.5 |

| DI44/133×180/28 | 133 × 180 | 415 | 0.57 | 200 | 2000 | 700 | 72 | 4.5 |

| DI23/146×180/28 | 146 × 180 | 230 | 1.59 | 350 | 1800 | 900 | 72 | 5.3 |

| DI44/146×180/28 | 146 × 180 | 415 | 0.99 | 350 | 1850 | 950 | 72 | 5.3 |

Our Manufacturing Process

Precision at Every Step — From Winding to Delivery

At VBM Enterprises, every product goes through a systematic, quality-controlled process to ensure high performance, durability, and safety. Here’s how we bring excellence to every fan and motor we build:

Step 1: Coil Winding & Motor Assembly

We begin with precision winding of coils to create efficient fan motors, followed by connecting lead wires to ensure electrical integrity.

Step 2: Motor Testing

Every motor undergoes Ohm value testing to check coil resistance, ensuring proper functionality from the start.

Step 3: Hi-POT & Impulse Testing

We perform high-potential and impulse testing to verify insulation strength between coils and motor casings, enhancing product safety and reliability.

Step 4: Motor Mounting & Impeller Balancing

Change the color to match your brand or vision, add your logo and more.

Step 5: Final Assembly & Quality Checks

Impellers are assembled to the motors, followed by pre-delivery inspections checking for vibration, wattage, and current to ensure optimal performance.

Step 6: Final Testing & Packing

A final round of Hi-POT insulation testing is conducted before products are carefully packed for delivery — guaranteeing both safety and quality in transit.

Let’s Build the Right Blower for You

At VBM Enterprises, every product goes through a systematic, quality-controlled process to ensure high performance, durability, and safety. Here’s how we bring excellence to every fan and motor we build: