| Parameter | Specification |

|---|---|

| Airflow Range | Up to [X] CFM (customizable) |

| Diameter | [Range: e.g., 200 mm – 1000 mm] |

| Voltage Options | 230V / 415V (Single & Three-Phase) |

| Speed | [e.g., 1400 RPM / 2800 RPM] |

| Mounting | Wall / Duct / Panel Mount |

| Motor Type | External Rotor Motor (CE Certified) |

Axial Flow Fans

At VBM Enterprises, our Axial Flow Fans are designed to deliver large volumes of air with low-pressure resistance, making them the ideal solution for ventilation, cooling, and exhaust systems across industries.

Built with aerodynamic precision and CE-certified components, our axial fans ensure quiet operation, long service life, and high energy efficiency—even in demanding industrial environments.

High Volume Airflow | Compact Design | Efficient Performance

Applications:

HVAC systems, general ventilation, heat exchangers, cooling towers.

Accessories Available

Frames, Housings, Flats, Basket Grills

Key Feature

- High Airflow Capacity with Low Power Consumption

- Compact and Lightweight Design for Easy Installation

- Durable Aluminum or Plastic Impellers

- Corrosion-Resistant Casing for Long-Term Reliability

- Custom Blade Sizes and Mounting Options Available

- Available in Single or Three-Phase External Rotor Motor Drives

Applications

- HVAC Systems

- Industrial Ventilation

- Exhaust & Air Circulation Systems

- Heat Exchangers

- Cooling Towers

- Greenhouses

- Cold Storage Units

- Generator Rooms

- Air Handling Units (AHUs)

1 or5

Blades Welded

30%

Nylon blade glass filled

6.3Grade

ISO 1940 Guidelines

Model Description

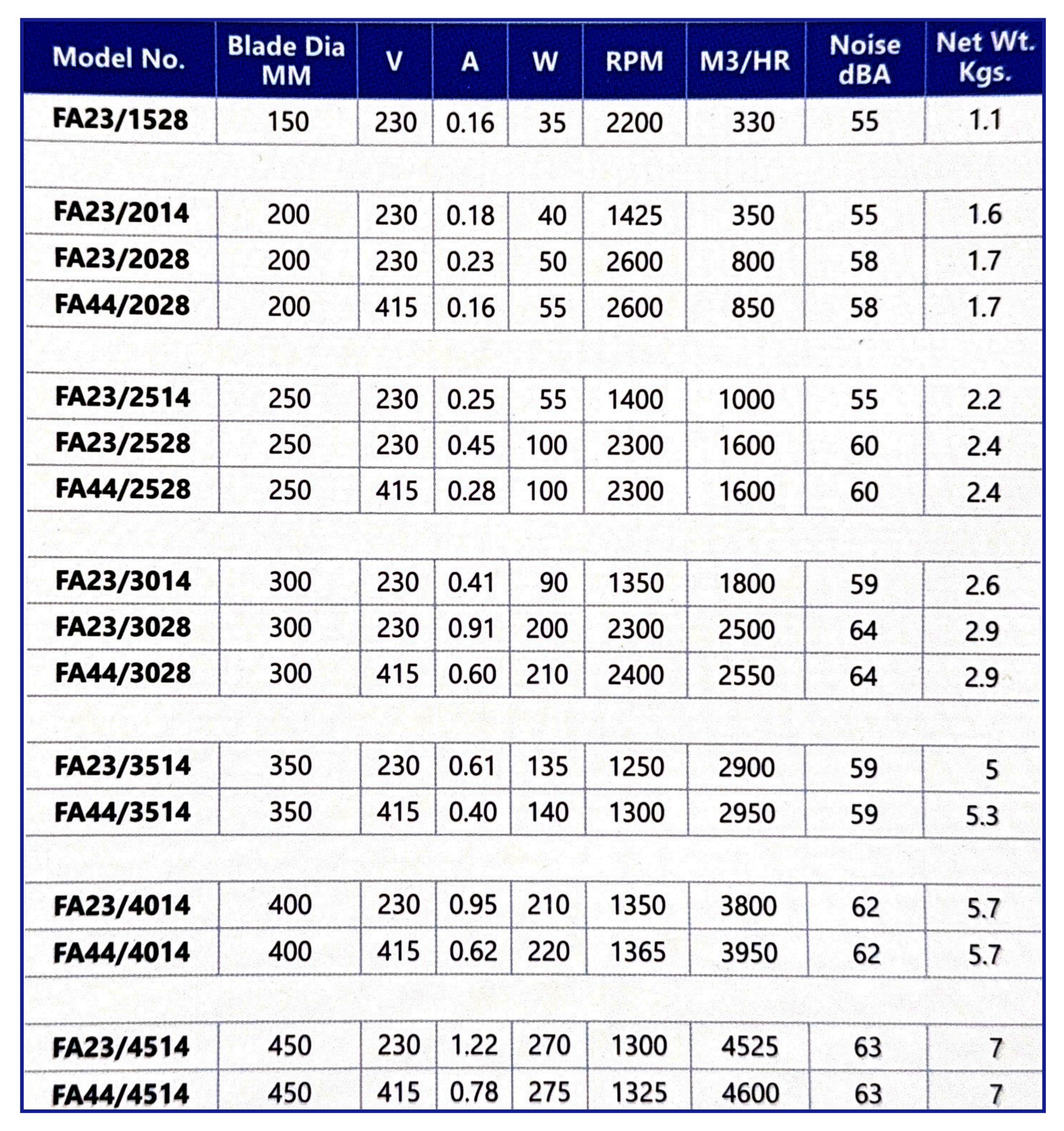

| Model No. | Blade Dia (MM) | V (Volts) | A (Amps) | W (Watts) | RPM | M³/HR | Noise (dBA) | Net Wt. (Kgs) |

|---|---|---|---|---|---|---|---|---|

| FA23/1528 | 150 | 230 | 0.16 | 35 | 2200 | 330 | 55 | 1.1 |

| FA23/2014 | 200 | 230 | 0.18 | 40 | 1425 | 350 | 55 | 1.6 |

| FA23/2028 | 200 | 230 | 0.23 | 50 | 2600 | 800 | 58 | 1.7 |

| FA44/2028 | 200 | 415 | 0.16 | 55 | 2600 | 850 | 58 | 1.7 |

| FA23/2514 | 250 | 230 | 0.25 | 55 | 1400 | 1000 | 55 | 2.2 |

| FA23/2528 | 250 | 230 | 0.45 | 100 | 2300 | 1600 | 60 | 2.4 |

| FA44/2528 | 250 | 415 | 0.28 | 100 | 2300 | 1600 | 60 | 2.4 |

| FA23/3014 | 300 | 230 | 0.41 | 90 | 1350 | 1800 | 59 | 2.6 |

| FA23/3028 | 300 | 230 | 0.91 | 200 | 2300 | 2500 | 64 | 2.9 |

| FA44/3028 | 300 | 415 | 0.60 | 210 | 2400 | 2550 | 64 | 2.9 |

| FA23/3514 | 350 | 230 | 0.61 | 135 | 1250 | 2900 | 59 | 5.0 |

| FA44/3514 | 350 | 415 | 0.40 | 140 | 1300 | 2950 | 59 | 5.3 |

| FA23/4014 | 400 | 230 | 0.95 | 210 | 1350 | 3800 | 62 | 5.7 |

| FA44/4014 | 400 | 415 | 0.62 | 220 | 1365 | 3950 | 62 | 5.7 |

| FA23/4514 | 450 | 230 | 1.22 | 270 | 1300 | 4525 | 63 | 7.0 |

| FA44/4514 | 450 | 415 | 0.78 | 275 | 1325 | 4600 | 63 | 7.0 |

Our Manufacturing Process

Precision at Every Step — From Winding to Delivery

At VBM Enterprises, every product goes through a systematic, quality-controlled process to ensure high performance, durability, and safety. Here’s how we bring excellence to every fan and motor we build:

Step 1: Coil Winding & Motor Assembly

We begin with precision winding of coils to create efficient fan motors, followed by connecting lead wires to ensure electrical integrity.

Step 2: Motor Testing

Every motor undergoes Ohm value testing to check coil resistance, ensuring proper functionality from the start.

Step 3: Hi-POT & Impulse Testing

We perform high-potential and impulse testing to verify insulation strength between coils and motor casings, enhancing product safety and reliability.

Step 4: Motor Mounting & Impeller Balancing

Change the color to match your brand or vision, add your logo and more.

Step 5: Final Assembly & Quality Checks

Impellers are assembled to the motors, followed by pre-delivery inspections checking for vibration, wattage, and current to ensure optimal performance.

Step 6: Final Testing & Packing

A final round of Hi-POT insulation testing is conducted before products are carefully packed for delivery — guaranteeing both safety and quality in transit.

Let’s Build the Right Blower for You

At VBM Enterprises, every product goes through a systematic, quality-controlled process to ensure high performance, durability, and safety. Here’s how we bring excellence to every fan and motor we build: